Features of Richconn disc springs

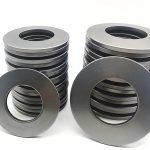

Conical Design: The unique conical design of the disc spring allows it to elastically deform under force and return to its original shape when the load is removed.

High Load Capacity: Compared to their size, disc springs are able to withstand high loads.

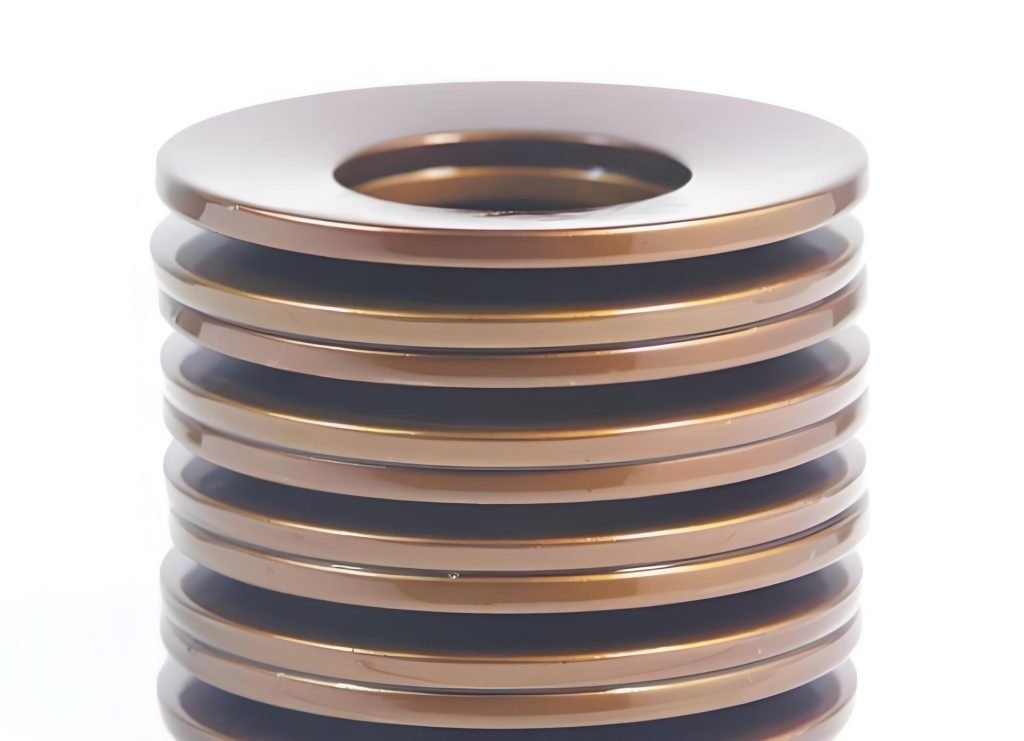

Stacked Configurations: Multiple stacked configurations (parallel, series, or combination) are available to achieve desired load and deflection characteristics.

Durability: Typically made of high carbon steel, stainless steel or other alloys, they are highly durable and can be used in harsh conditions.

Adjustable stiffness: The stiffness of disc springs can be adjusted by varying thickness, diameter and material.

Our Services

Our Services