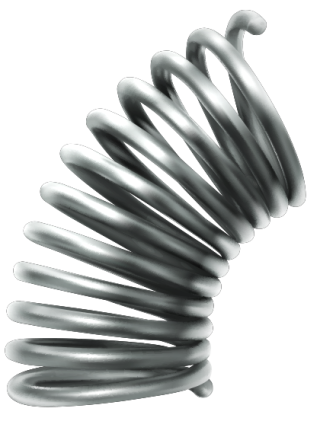

Startseite " Zugfeder

Customization: Richconn offers highly tailored tension spring solutions to meet specific client requirements.

Expertise: Our experienced team utilizes advanced technology for precise and reliable spring manufacturing.

Quality: We use high-quality materials to ensure optimal performance and durability of our springs.

Versatility: Richconn provides springs for various applications, including industrial, automotive, and specialized machinery.

Efficiency: Our precision-engineered springs enhance the efficiency and longevity of your products.

Richconn is one of China’s foremost manufacturers of tension springs, known for our expertise and high standards in the industry. We have built a solid reputation by consistently delivering superior quality products that meet the diverse needs of our clients. Our state-of-the-art facilities and advanced manufacturing processes ensure that we stay at the forefront of spring technology.

At Richconn, we pride ourselves on offering highly customized tension spring solutions. Our team of experts works closely with clients to understand their specific requirements and develop springs that perfectly match their applications. Whether for industrial machinery, automotive components, or specialized equipment, our custom springs provide optimal performance and durability.

Our commitment to excellence extends beyond product quality to include exceptional customer service. We use the best materials and rigorous quality control measures to ensure the reliability of our springs. With Richconn, clients can expect innovative spring solutions, timely delivery, and ongoing support to ensure their complete satisfaction.

Feder Konstante: denoted by k, the load in kgf/mm per 1 mm distance increase when the spring is stretched.

Spring Constant Formula (unit: kgf/mm): k=(G*d4)/(8*Dm3*Nc)

G: steel modulus of the wire; d: wire diameter; Dm: center diameter = outer diameter – wire diameter; Nc: effective number of turns = total number of turns – 2.

Initial Tension of Tension Springs: Initial tension is the force required to just separate the coils that are in close contact. This initial tension is developed after the spring is coiled. Due to variations in wire material, diameter, spring index, static electricity, lubricants, heat treatment, and plating, the initial tension in each tension spring may vary. Therefore, when installing tension springs of different specifications, they should be pre-extended so that there is a slight gap between the coils. The force required at this point becomes the initial tension.

Initial tension = P-k X l = Maximum load – spring constant X extension length

Various end devices or “hooks” are used to ensure the source of tension for tension springs. Tension springs operate in a manner opposite to that of compression springs. While compression springs exert a force when compressed, tension springs exert a force when extended or pulled apart. When the ends of a tension spring are pulled apart, the spring attempts to pull them back together. Like Druckfedern, tension springs also absorb and store energy. However, unlike compression springs, most tension springs are typically under a certain amount of tension even without any load. This initial tension determines how tightly the tension spring is coiled in the absence of any load.

| Material | Kohlenstoffstahl: 70, 72A, 72B, 82B, importierter Klavierdraht, T9A, SWPB, WPC, 65Mn Allgemeiner legierter Stahl: 60Si2MnA, 50CrVA, 55CrSiA, 60CrMnA, 60Cr2VA Rostfreier Stahl: SUS302, SUS304, SUS316, SUS631, 17-7PH Hochtemperaturlegierung: 30W4Cr2VA, Inconel X750, Inconel 718, Nimonic90 Kupfer-Legierung: Berylliumkupfer, Phosphorbronze usw. Eisendraht: verzinkter Eisendraht |

| Endstile | (Hakenformen) Geschliffen und geschlossen gewickelt, ungeschliffen und geschlossen gewickelt, geschliffen und nicht geschlossen gewickelt, zentrierter Rundhaken, versetzter Rundhaken, halber Rundhaken usw. Siehe Diagramm für Federenden |

| Material Bereich | Drahtdurchmesser: φ0,3-80 mm; Blechdicke: δ0,1-25mm |

| Richtung der Spule | Links/Rechtshänder, standardmäßig rechts; Aktive Spulen, Gesamtanzahl der Spulen |

| Kraftanforderungen | Feder anbringen Zeichnungsstil |

| Besondere Anforderungen | Ermüdungslebensdauer, Hochtemperaturbeständigkeit, Behandlung bei starkem Druck und konstanter Temperatur, Anforderungen an die Korrosionsbeständigkeit |

| Oberflächenbehandlung | Verzinkung, Verchromung, Vernickelung, Elektrophorese, Lackierung, Pulverbeschichtung, Schwärzen, Ölen, Dacromet usw. |

| Verpackungsmethode | Innere Verpackung: PVC-Beutel oder Luftpolsterfolie; Außenverpackung: Karton, Gewebesack oder Palette |

| Qualitätssystem | Zertifizierung des internationalen Qualitätssystems ISO9001-2008 |

| Erforderliche Menge | Es ist wünschenswert, dass die Kunden bei der Anfrage die gewünschten Mengen angeben; größere Mengen werden bevorzugt. |

| Transport Methode | Kurierdienst, Logistik oder andere im gegenseitigen Einvernehmen vereinbarte Methoden |

The first step in our custom torsion spring process is to confirm the specifications. This begins with a detailed consultation where our expert team discusses your specific requirements, including dimensions, materials, load requirements, and the intended application of the springs. After understanding your needs, our engineers will provide a custom design and specifications for your approval. Once the design is approved, we will provide a detailed quotation based on the confirmed specifications and order quantity.

Upon approval of the specifications and receipt of your order, we proceed to the production phase. We start by selecting the appropriate high-quality materials for your torsion springs. Utilizing advanced technology and precise manufacturing processes, our skilled technicians produce the custom torsion springs to exacting standards. Throughout the production process, we conduct stringent quality checks to ensure that each spring meets the specified standards and performs reliably in its intended application.

Once the production of your custom torsion springs is complete, we carefully package the springs to prevent any damage during transit. We then arrange for prompt and secure shipping to your specified location, whether domestic or international. To ensure your complete satisfaction, we offer comprehensive after-sales support, ready to address any questions or concerns you may have after receiving your order.

Häufig gestellte Fragen Haben Sie eine Frage?

Häufig gestellte Fragen Haben Sie eine Frage?To ensure accurate manufacturing, we need details such as the spring's dimensions (wire diameter, coil diameter, and total length), material type, load requirements, and the specific application.

Custom tension springs are used in various industries, including automotive, aerospace, industrial machinery, medical devices, and consumer products.

Yes, our experienced engineering team can assist with design and optimization to ensure the springs meet your exact requirements and perform reliably in your application.

We are equipped to handle large volume orders efficiently with our advanced manufacturing capabilities. We ensure consistent quality and timely delivery, regardless of order size.

We implement rigorous quality control measures, including material testing, dimensional inspections, and load testing, to ensure our springs meet the highest standards of performance and durability.

Unsere Dienstleistungen

Unsere DienstleistungenRaum 401, Gebäude C, Nr. 16 Wangjiao Road, Hengtang, Tangxia Town, Dongguan City, Provinz Guangdong, China

Melden Sie sich an, um Updates und Neuigkeiten über uns zu erhalten

Urheberrecht 2024 Richconn Frühling. Alle Rechte vorbehalten.