Startseite " Torsionsfeder

At Richconn, we specialize in providing high-quality custom torsion springs tailored to meet your specific needs. Our advanced manufacturing processes and state-of-the-art equipment ensure that each torsion spring is crafted with precision and durability in mind. Whether you require unique specifications for automotive, industrial, or consumer applications, our expert team works closely with you to deliver solutions that exceed your expectations. With a commitment to excellence and customer satisfaction, Richconn is your trusted partner for all your custom torsion spring requirements.

Advanced Manufacturing Technology: Richconn employs cutting-edge technology and state-of-the-art equipment in the production of torsion springs, ensuring precision, quality, and consistency in every product.

Customization and Flexibility: We offer highly customizable solutions tailored to meet the specific requirements of our clients across various industries, including automotive, industrial, and consumer applications.

Experienced and Skilled Team: Our team of experienced engineers and skilled technicians bring a wealth of knowledge and expertise to every project, ensuring that we deliver innovative and reliable solutions.

Strict Quality Control: Richconn adheres to stringent quality control processes throughout the manufacturing cycle, guaranteeing that our torsion springs meet international standards and exceed customer expectations.

Comprehensive Customer Support: We are committed to providing exceptional customer service, from the initial consultation through to after-sales support, ensuring a seamless and satisfying experience for our clients.

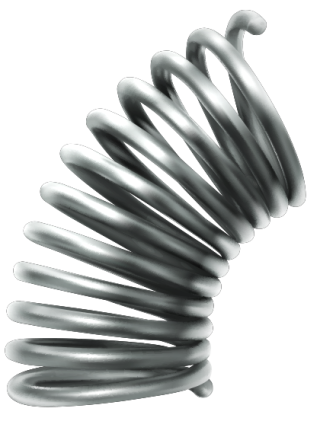

Torsion springs are a type of helical spring that generate torque or rotational force. The ends of these springs are attached to other components, and when these components rotate around the spring’s center, the spring pulls them back to their original position. Torsion springs can store and release angular energy or apply static force by rotating around the spring body axis. Typically, these springs are closely wound, but they may have a pitch between coils to reduce friction. They resist rotational forces and can be designed to wind in either a clockwise or counterclockwise direction, depending on application requirements. The coils can either be tightly wound or spaced apart to accommodate torsional loads perpendicular to the spring axis. The ends of the spring can be formed into hooks or straight torsion arms.

Designing torsion springs involves considering several key parameters, as the complexity and variation from single to double torsion springs, including various torsion bars, require precise design information:

Important Specifications: When specifying a torsion spring, include the wire diameter (d), outer diameter (D), arm length (L), free height (Lo), and other geometric dimensions such as torque arms (T1, T2, … Tj) and corresponding torsion angles (Ψ).

Torsion springs are mechanical components that operate using elasticity, typically made from spring steel. They are widely used to control the movement of machine parts, cushion impacts or vibrations, store energy, and measure force. These versatile springs find applications across various industries including computers, electronics, household appliances, cameras, instruments, doors, motorcycles, harvesters, and automobiles.

To produce high-quality torsion springs, we utilize advanced production equipment such as:

This advanced equipment ensures the precision and reliability of torsion springs in meeting the diverse needs of these industries.

| Material | Kohlenstoffstahl: 70, 72A, 72B, 82B, importierter Klavierdraht, T9A, SWPB, WPC, 65Mn Allgemeiner legierter Stahl: 60Si2MnA, 50CrVA, 55CrSiA, 60CrMnA, 60Cr2VA Rostfreier Stahl: SUS302, SUS304, SUS316, SUS631, 17-7PH Hochtemperaturlegierung: 30W4Cr2VA, Inconel X750, Inconel 718, Nimonic90 Kupfer-Legierung: Berylliumkupfer, Phosphorbronze usw. Eisendraht: verzinkter Eisendraht |

| Endstile | (Hakenformen) Geschliffen und geschlossen gewickelt, ungeschliffen und geschlossen gewickelt, geschliffen und nicht geschlossen gewickelt, zentrierter Rundhaken, versetzter Rundhaken, halber Rundhaken usw. Siehe Diagramm für Federenden |

| Material Bereich | Drahtdurchmesser: φ0,3-80 mm; Blechdicke: δ0,1-25mm |

| Richtung der Spule | Links/Rechtshänder, standardmäßig rechts; Aktive Spulen, Gesamtanzahl der Spulen |

| Kraftanforderungen | Feder anbringen Zeichnungsstil |

| Besondere Anforderungen | Ermüdungslebensdauer, Hochtemperaturbeständigkeit, Behandlung bei starkem Druck und konstanter Temperatur, Anforderungen an die Korrosionsbeständigkeit |

| Oberflächenbehandlung | Verzinkung, Verchromung, Vernickelung, Elektrophorese, Lackierung, Pulverbeschichtung, Schwärzen, Ölen, Dacromet usw. |

| Verpackungsmethode | Innere Verpackung: PVC-Beutel oder Luftpolsterfolie; Außenverpackung: Karton, Gewebesack oder Palette |

| Qualitätssystem | Zertifizierung des internationalen Qualitätssystems ISO9001-2008 |

| Erforderliche Menge | Es ist wünschenswert, dass die Kunden bei der Anfrage die gewünschten Mengen angeben; größere Mengen werden bevorzugt. |

| Transport Methode | Kurierdienst, Logistik oder andere im gegenseitigen Einvernehmen vereinbarte Methoden |

The first step in our custom torsion spring process is to confirm the specifications. This begins with a detailed consultation where our expert team discusses your specific requirements, including dimensions, materials, load requirements, and the intended application of the springs. After understanding your needs, our engineers will provide a custom design and specifications for your approval. Once the design is approved, we will provide a detailed quotation based on the confirmed specifications and order quantity.

Upon approval of the specifications and receipt of your order, we proceed to the production phase. We start by selecting the appropriate high-quality materials for your torsion springs. Utilizing advanced technology and precise manufacturing processes, our skilled technicians produce the custom torsion springs to exacting standards. Throughout the production process, we conduct stringent quality checks to ensure that each spring meets the specified standards and performs reliably in its intended application.

Once the production of your custom torsion springs is complete, we carefully package the springs to prevent any damage during transit. We then arrange for prompt and secure shipping to your specified location, whether domestic or international. To ensure your complete satisfaction, we offer comprehensive after-sales support, ready to address any questions or concerns you may have after receiving your order.

Häufig gestellte Fragen Haben Sie eine Frage?

Häufig gestellte Fragen Haben Sie eine Frage?Torsion springs are used in various applications to store and release rotational energy. They are commonly found in automotive components, industrial machinery, and consumer products like garage doors and clipboards.

Yes, Richconn specializes in custom torsion springs. We work closely with our clients to design and manufacture springs that meet their unique specifications and requirements.

The lead time for custom torsion springs varies depending on the complexity and quantity of the order. Typically, it ranges from a few weeks to a couple of months. We provide estimated lead times during the consultation process.

To provide an accurate quote, we need details such as the spring's dimensions, material, load requirements, application, and any special requirements you may have.

You can contact us through our website or customer service to discuss your requirements. Our team will guide you through the process from consultation to final delivery.

Unsere Dienstleistungen

Unsere DienstleistungenRaum 401, Gebäude C, Nr. 16 Wangjiao Road, Hengtang, Tangxia Town, Dongguan City, Provinz Guangdong, China

Melden Sie sich an, um Updates und Neuigkeiten über uns zu erhalten

Urheberrecht 2024 Richconn Frühling. Alle Rechte vorbehalten.