Springs are used in a great number of items in our daily lives, including timepieces, mattresses, automobiles, and industrial machinery. Investigating the concepts of mechanics and material science is necessary to comprehend how springs operate. The fundamentals of spring mechanics, spring kinds, and applications are covered in detail in this article.

Fundamental Ideas of Springs

A spring is fundamentally an elastic device that stores mechanical energy. A distorted spring exerts force in an attempt to revert to its former shape. Hooke’s Law, which stipulates that, as long as the deformation stays within the material’s elastic limit, the force applied by a spring is precisely proportionate to its displacement, explains this phenomenon. In terms of math, this is stated as:

F=−kx

where x is the displacement from the equilibrium position, F is the force that the spring exerts, and k is the spring constant, a measurement of the spring’s stiffness.

The spring’s force acting in the opposite direction of the displacement is indicated by the negative sign.

What is the physics behind springs?

Springs function according to basic physics principles. A spring undergoes work when a force is applied to stretch or compress it; this work is then stored as potential energy. The spring’s material composition and geometry contribute to its capacity to store energy. The spring returns to its natural shape when the force is withdrawn because the stored potential energy is released. The degree of deformation, the spring’s design, and the elasticity of the material are some of the variables that affect how well this energy storage and release mechanism works.

Hooke’s Law and Elasticity

The ability of a substance to regain its previous shape after deformation is referred to as elasticity. As long as the spring stays within its elastic limit, Hooke’s Law describes the relationship between the force applied to it and the displacement that results. If this limit is exceeded, the material can permanently distort and become incapable of taking on its former shape.

Possibility of Energy Storage

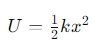

A spring stores energy as potential energy when it is distorted. The following formula can be used to determine the potential energy contained in a linear spring:

where x is the displacement from the equilibrium position, U is the potential energy, and k is the spring constant.

When the spring reverts to its initial configuration, the stored energy is what enables it to function.

What makes springs springy?

There are multiple reasons for a spring’s “springiness,” or its capacity to undergo deformation before reverting to its initial form:

Material Characteristics

High-elasticity materials, including high-carbon steel, stainless steel, and other alloys, are commonly used to make springs. These materials have the ability to withstand large deformations and still regain their original shape. The spring’s overall performance and spring constant are influenced by the material selection.

Pattern and Form

A spring’s behavior is greatly influenced by its design. The overall length, number of coils, wire diameter, and coil diameter are important design characteristics. These elements affect the spring’s response to applied forces and establish its spring constant. For example, a spring that has more coils or a greater coil diameter will generally be less stiff and have a lower spring constant, which will allow it to deform more easily.

Production Method

A spring’s characteristics are also affected by the manufacturing process. The strength and elasticity of the material can be increased through processes like heat treatment and cold working, which will improve the performance of the spring. The spring will function dependably under load and have constant qualities thanks to precision production.

Springs Types

Springs are available in a variety of sizes and shapes, each intended for a particular use. The most prevalent kinds of springs are as follows:

1. compression springs

Because of their compressive load-bearing design, these springs shrink in length when under load. They are frequently utilized in applications like mattress coils and car suspensions where a pushing or compressing force is needed.

2. Springs for tension

The purpose of tension springs is to retain and absorb energy during separation. When the force is released, they take on their original shape once more. These springs are frequently utilized in trampolines and other similar applications where the spring extends and then retracts to its initial configuration.

3. Springs in Torsion

To operate, torsion springs revolve around their axis. They are commonly utilized in systems for garage doors and clothespins, among other applications where a rotational force is required.

4. The Leaf Springs

Leaf springs, which are frequently used in car suspension systems, are made of many layers of metal. When a weight is applied, they bend to give support and absorb shock.

5. Coil Springs

A coil spring is a mechanical elastic component made by winding metal wire (usually steel or stainless steel) into a helical shape to store mechanical energy. When an external force is applied, the coil spring deforms and returns to its original shape once the force is removed. This elastic property makes coil springs widely used in various mechanical devices to absorb shock and vibration, provide return force, and maintain constant pressure or tension.

Design and Material Considerations

A spring’s performance is largely determined by the material used in its construction. High-carbon steel, stainless steel, and different alloys that are selected for their flexibility, strength, and durability are common materials. A spring’s design also takes into account factors like wire diameter, coil diameter, number of coils, and overall length, all of which have an impact on the spring constant and how the spring behaves under stress.

Applications for Springs: Springs are essential to many systems and gadgets. Here are a few instances:

1. Automobile Sector

Springs provide a smooth ride and absorb stress in suspension systems, which are crucial components of automobiles. Additionally, they are utilized in brakes and engine systems.

2. Goods for Consumers

Springs are used to activate the click mechanism in pens and to store and release energy in watches so that the time is kept accurately. They are present in many commonplace products.

3. Equipment for Industry

Springs are frequently used in heavy machinery to manage tension, absorb shock, and maintain pressure, among other tasks.

4. Health Care Equipment

Springs assist in controlling the flow of medication in a variety of medical equipment, such as insulin pens and inhalers.

Springs provide an intriguing illustration of the numerous ways in which basic mechanical concepts can be used to address real-world issues. They carry out essential tasks in a myriad of gadgets and systems by storing and releasing energy, improving the efficiency and convenience of modern living. We may better appreciate springs’ widespread presence and the ingenious engineering that goes into their design and application when we comprehend the basic concepts underlying how they operate.