The “compression height” or “solid height” of a spring is a crucial phrase that frequently comes up while talking about springs. Engineers, designers, and anybody else engaged in the selection or application of springs has to understand this idea because it directly affects the spring’s performance and appropriateness for a given application.

What is meant by “spring compression height”?

The length of a compression spring at maximum compression is referred to as spring compression height. Put differently, it is the height of the spring at which no more compression can occur and all of the coils are in contact with one another. This measurement is important because it shows the lowest point at which a spring can operate, which has an impact on the applications of the spring in different mechanical systems.

Design and Application Importance

Space Restrictions: The amount of space that a spring has to work with is one of the main factors to be taken into account while designing a spring. When a spring is fully compressed, the compression height helps determine whether it will fit inside the allotted space. An excessively high compression height could cause the spring to become misaligned within the assembly, which could result in malfunctions or harm to the neighboring parts.

Load Capacity: The spring’s ability to support a given load is directly correlated with its compression height. A spring releases its mechanical energy when it expands back to its initial height after being squeezed. One of the most important factors in deciding whether a spring is suitable for a given application is its load capacity at its compression height. For example, in car suspension systems, the compression height needs to be precisely measured to make sure the spring can bear the car’s weight without collapsing.

Durability and Fatigue: Determining a spring’s durability and fatigue life also requires an understanding of its compression height. Regularly compressing springs to their maximum height might put them under more stress and hasten wear or failure. As a result, over the spring’s operational life, designers must take into account not only the highest load the spring can support but also the frequency at which the spring will be compressed to its solid height.

Safety Considerations: Preventing the spring from reaching its compression height during regular operation is a common safety precaution. Unexpectedly compressing a spring to its maximum capacity can result in mechanical failure or put operators’ safety at risk. This is particularly important for applications where spring failure might have catastrophic effects, such as industrial machinery, automotive systems, and aircraft components.

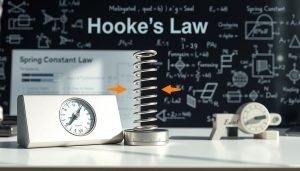

Measurement and Calculation

The pitch, total number of coils, and wire diameter of a spring must all be taken into account when calculating the compression height of the spring. To determine the compression height, use the following formula:

Height of Compression = Total Coils × Wire Diameter

When the spring is at its solid height, all of the coils are totally in contact with one another, which is the assumption made by this formula. In actuality, the compression height might be marginally higher because of things like residual gaps between coils and coil deformation.

One important feature that is essential to a spring’s operation and appropriateness for a given set of uses is its compression height. Engineers can guarantee that the spring will function as intended, fit into the allotted space, and have a long operational life by carefully taking this measurement into account during the design phase. Whether it is utilized in consumer goods, automotive systems, or industrial apparatus, the compression height is an important factor that should not be disregarded.