The aircraft idle system is key to an airplane’s engine. Knowing how it works is vital for keeping planes running smoothly. The idle spring is a major player in this system, helping control the engine’s idle speed.

We’ll dive into the aircraft idle system, focusing on the idle spring and its role. This knowledge helps maintenance teams keep engines running well. It’s all about keeping the plane safe and efficient.

In this article, we’ll explore the aircraft idle system and its components. We’ll look at the idle spring and its importance. By the end, you’ll know how to keep these systems running at their best.

Understanding the Basics of Aircraft Engine Idle Systems

Aircraft engine idle systems are key for keeping engines running well when they’re not moving. They help control engine speed, use fuel efficiently, and cut down on emissions. Knowing how these systems work is vital for making aircraft engines run better and for the plane’s overall performance.

The main parts of idle control systems are springs and valves. They work together to manage airflow and fuel. It’s important that these parts work right to keep the engine stable when it’s idling. This helps aircraft engineers understand why idle control systems are so important in aviation engineering.

Key Components of Idle Control Systems

- Springs: regulate airflow and fuel flow

- Valves: control the flow of air and fuel into the engine

The Role of Springs and Valves in Engine Operation

Springs and valves help engines run smoothly when they’re not moving. They make sure the engine uses fuel well and doesn’t pollute too much. In the world of idle control systems, aviation engineering is key to making these parts work their best.

Primary Functions and Importance

The main job of idle control systems is to keep the engine stable when it’s not moving. This is important for keeping the engine running well, saving fuel, and reducing pollution. By knowing how important idle control systems are, aircraft engineers can make sure these systems are always in top shape. This helps the engine and the whole plane run better.

| Component | Function | Importance |

|---|---|---|

| Springs | Regulate airflow and fuel flow | Critical for maintaining stable engine operation |

| Valves | Control the flow of air and fuel into the engine | Essential for optimal engine performance and efficiency |

How Does the Idle Spring and Valve Control Idle Aircraft Performance

The idle spring and valve are key to controlling how an aircraft idles. The idle spring keeps the engine speed steady. The idle valve makes sure the engine smoothly moves from idle to normal speed.

A good idle spring stops problems like rough idling or stalling. The idle valve controls the air-fuel mix, which is vital for engine performance. If the idle valve fails, the engine might not run well, use more fuel, and pollute more.

Several things can affect how well the idle spring and valve work. These include:

- Idle spring tension

- Idle valve calibration

- Air-fuel mixture

Knowing how the idle spring and valve control the engine helps pilots and mechanics. They can then work to improve engine performance and keep flights safe and efficient. Regular checks on these parts are key to avoiding problems and keeping the engine running well.

In summary, the idle spring and valve are essential for good engine performance and smooth idling. Keeping these parts in good shape is important. It helps pilots and mechanics ensure the engine runs well and keeps flights safe.

| Component | Function | Importance |

|---|---|---|

| Idle Spring | Regulates idle speed | Critical for smooth idle operation |

| Idle Valve | Regulates air-fuel mixture | Vital for optimal engine performance |

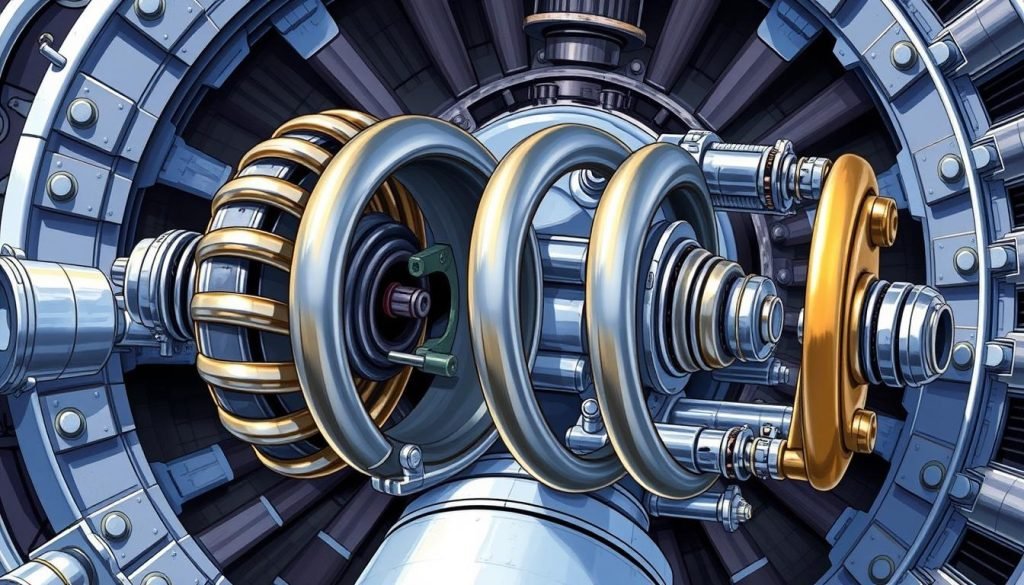

The Anatomy of Aircraft Idle Springs

Aircraft idle springs are key to keeping engines running smoothly. Their design and function are vital for a smooth idle. These springs are made from materials chosen for their strength and durability.

The type of material used in idle springs is very important. High-strength alloys and stainless steel are common. They resist corrosion and fatigue well. The spring’s construction, including wire and coil size, also matters a lot.

Spring Materials and Construction

The materials and how the spring is built are both critical. The spring rate, or stiffness, affects how well the spring works. A stiffer spring resists compression better, while a softer one compresses more easily.

Compression mechanisms, like coil binders, keep the spring in shape. They prevent damage from too much compression.

Tension and Compression Mechanisms

The tension and compression parts of idle springs work together. Tension devices, like spring tensioners, keep the spring tight. Compression mechanisms, like shock absorbers, soften the impact of compression.

This balance ensures the springs work well, even under tough conditions. Knowing about these parts helps keep aircraft engines running well.

Understanding aircraft idle springs is key to their performance. The right materials and construction, along with balanced tension and compression, are essential. This ensures reliable and consistent performance, keeping aircraft engines safe and efficient.

Essential Functions of Idle Control Valves

Idle control valves are key in keeping the engine running smoothly. They control the air and fuel going into the engine. This ensures the engine runs at a steady speed, preventing it from stalling.

The valves work with other parts to make sure the engine runs well. They help control airflow and fuel flow. This is vital for the engine’s performance.

Idle control valves are important for the engine’s smooth operation. They help prevent stalls and keep the engine running smoothly. This is because they control the air and fuel flow.

These valves work with other parts like idle springs. Together, they help the engine run at its best. This is important for the engine’s performance.

Knowing how idle control valves work is key for fixing engine problems. It helps keep the engine running smoothly and safely. This is important for aircraft operators.

In short, idle control valves are vital for the engine’s performance. They help keep the engine running smoothly and prevent stalls. By understanding their role, aircraft operators can keep their engines running well.

| Component | Function |

|---|---|

| Idle Control Valves | Regulate airflow and fuel flow to maintain consistent engine speed |

| Idle Springs | Provide tension to maintain consistent engine speed |

The Relationship Between Idle Springs and Fuel Flow

Idle springs are key to managing fuel flow, which is vital for the engine’s efficiency. They work with the fuel system to keep fuel flow steady, even when the engine is idling. This partnership is essential for keeping the engine running well and avoiding damage.

The fuel flow is controlled by the idle springs, which keep the pressure consistent. This consistent pressure is critical for the engine to get the right fuel amount, even when idling. Fuel pressure regulation is vital for engine performance, and idle springs are a big part of it.

Fuel Pressure Regulation

Fuel pressure regulation is key to engine efficiency. The idle springs help manage this pressure, ensuring the engine gets the right fuel. This is critical for preventing engine damage and keeping performance optimal.

Impact on Engine Performance

The connection between idle springs and fuel flow greatly affects engine performance. If the idle springs don’t work right, it can cause poor engine performance, lower fuel efficiency, and even engine damage. So, it’s vital to make sure the idle springs are working well to keep the engine running efficiently.

Efficiency Considerations

The link between idle springs and fuel flow is also important for efficiency. The idle springs help control fuel flow, ensuring the engine gets the right amount of fuel. This control is key for maintaining engine efficiency and avoiding waste. By ensuring the idle springs are working correctly, engine efficiency can be improved, leading to better performance and less fuel use.

Common Issues with Idle Control Systems

Idle control systems are key for aircraft engines to work well. But, they can face common problems that hurt performance. Troubleshooting these issues is key to keep the engine running smoothly and healthy.

Some common issues with idle control systems include:

- Idle speed fluctuations

- Engine stalling

- Increased fuel consumption

- Decreased engine performance

These problems can come from many sources. This includes bad idle control valves, old springs, or dirty air filters.

To fix these issues, regular troubleshooting and upkeep are vital. This means checking the system for wear or damage, fixing or replacing bad parts, and making sure it’s set right.

Knowing about common idle control system problems and doing regular checks can help. It makes sure engines work well, lowers the chance of engine failure, and cuts down on downtime. Regular troubleshooting and upkeep can also spot issues early, saving time and money later on.

Regular maintenance is key to ensuring the optimal performance of idle control systems and preventing common issues from arising.

| Common Issue | Cause | Solution |

|---|---|---|

| Idle speed fluctuations | Faulty idle control valve | Replace the valve |

| Engine stalling | Clogged air filter | Clean or replace the air filter |

| Increased fuel consumption | Worn-out springs | Replace the springs |

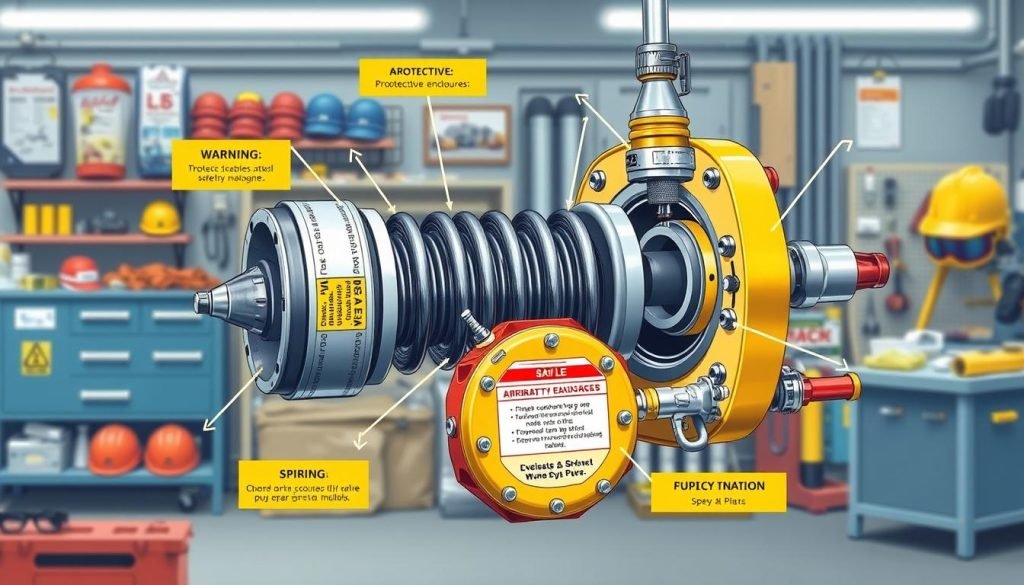

Maintenance Requirements for Idle Springs and Valves

To keep your engine running smoothly, it’s key to maintain idle springs and valves well. Regular checks are vital to spot problems early. Look for wear on the springs and valves and make sure they work right.

Here are some tips to keep your engine in top shape:

- Regularly clean and lubricate the idle springs and valves to prevent corrosion and wear

- Inspect the valves for proper alignment and function

- Check the idle springs for proper tension and compression

By sticking to these maintenance steps, you can keep your engine running well. This reduces the chance of engine failure and boosts efficiency.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Inspect idle springs and valves | Every 100 hours of flight time | High |

| Clean and lubricate idle springs and valves | Every 50 hours of flight time | Medium |

| Replace idle springs and valves as needed | As required | High |

Keeping idle springs and valves in good shape is essential for your aircraft’s performance and safety. By following these guidelines and keeping up with maintenance, you can avoid engine failure and ensure your engine runs at its best.

Optimizing Idle Performance in Different Weather Conditions

Knowing how weather conditions affect idle performance is key for aircraft engine care. Temperature, humidity, and air pressure can change engine efficiency and idle performance. Adjusting engine settings based on these factors is vital.

Monitoring and tweaking engine settings for weather changes is important. This includes adjusting fuel flow, ignition timing, and more. Doing this helps improve engine performance, cuts down on maintenance costs, and lowers engine damage risk.

- Adjust engine settings for temperature and humidity changes

- Apply special engine coatings to cut down friction and boost efficiency

- Stick to regular maintenance to keep engine parts in top shape

By being proactive in optimization and thinking about weather conditions effects, aircraft operators can enhance engine efficiency. They can also lower maintenance costs and ensure safe, reliable flights. Regular checks and adjustments of engine settings help avoid damage and improve idle performance in different weather.

Safety Considerations and Best Practices

When it comes to idle aircraft performance, safety considerations are key. To ensure a safe and efficient flight, following best practices is essential. This includes pre-flight checks and sticking to regulatory compliance. By doing this, pilots can lower the risk of accidents and make flights smoother.

Conducting detailed pre-flight checks is a critical safety step. This involves checking the engine, fuel system, and other vital parts to make sure they work right. Pilots also need to know emergency procedures and have a plan ready for any unexpected situations.

Some important safety tips and best practices are:

- Regular maintenance and inspection of aircraft parts

- Following regulatory compliance rules and guidelines

- Doing thorough pre-flight checks to make sure the aircraft is ready

- Training and planning for emergency procedures

By sticking to these guidelines and focusing on safety considerations, pilots can keep their flights safe and efficient. It’s also vital to keep up with new aircraft technology to keep improving safety.

Remember, safety is everyone’s job. By working together, we can make the aviation industry safer and more efficient.

| Safety Consideration | Best Practice |

|---|---|

| Pre-flight checks | Do thorough inspections of aircraft parts |

| Regulatory compliance | Follow standards and guidelines from regulatory bodies |

| Emergency procedures | Make and practice emergency plans regularly |

Modern Developments in Idle Control Technology

Idle control technology has seen big modern developments in recent years. This has changed how aircraft engines work. Now, thanks to innovation, makers have come up with new ways to make engines run better, save on maintenance, and work more efficiently.

Some major updates in idle control tech include:

- Advanced valve designs for better fuel flow control

- Stronger spring materials for longer life and reliability

- Integrated systems for top-notch performance

These modern developments help aircraft use less fuel, cut down on emissions, and get safer. As the aviation world keeps growing, we’ll likely see even more cool tech for idle control systems.

By using these new idle control technology advancements, plane operators can lead the way. They’ll enjoy better performance, lower maintenance costs, and more efficiency.

Conclusion: Mastering Aircraft Idle Control Systems

Mastering aircraft idle control systems is key for top engine performance and efficiency. Knowing about idle springs and valves helps pilots and aviation experts get the most from their planes. This knowledge is essential for keeping engines running smoothly.

This article has given you the tools to fix common idle control system problems. You now know how to improve idle performance in different weather. Staying current with new tech is also important. With this knowledge, pilots can improve their skills, make flying safer, and save on maintenance costs.

Remember to always put safety first and follow rules when working with idle control systems. By understanding these systems well, you’ll fly with more confidence and respect for the amazing technology that powers your plane.