The crucial mechanical characteristic that characterizes a spring’s stiffness is its spring rate, sometimes referred to as its spring constant. Determining how much a spring will compress or expand under a given weight is a key concept in physics and engineering. Designing and employing springs in a variety of applications, such as mechanical timepieces and car suspension systems, requires an understanding of spring rate.

Definition of Spring Rate

Spring rate (k) is defined as the amount of force (F) required to compress or extend a spring by a unit length (x). Mathematically, it is expressed by Hooke’s Law as:

F=k⋅x

where:

- F is the force applied to the spring,

- k is the spring rate,

- x is the displacement of the spring from its equilibrium position.

The unit of spring rate is typically Newtons per meter (N/m) in the metric system or pounds per inch (lb/in) in the imperial system.

Definition of Spring Rate

Spring rate (k) is defined as the amount of force (F) required to compress or extend a spring by a unit length (x). Mathematically, it is expressed by Hooke’s Law as:

Elements Affecting the Spring Rate

Numerous factors influence the spring rate of a specific spring, including:

Material: The spring’s stiffness is determined by the kind of material used in its construction. Springs made of materials with a higher elasticity modulus will be more rigid.

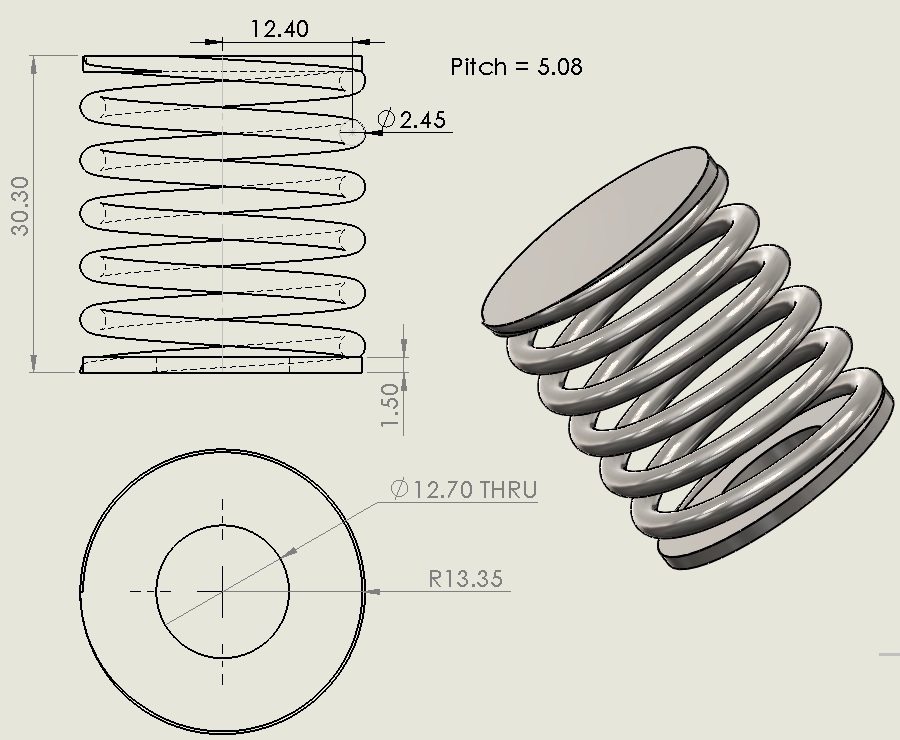

The coil diameter of a spring is an important factor to consider. In general, lower spring rates result from larger coil diameters, which lessen the spring’s stiffness.

Wire Diameter: Because thicker wires resist deformation more successfully, they spring more quickly.

Number of Coils: A spring with more coils typically has a lower spring rate because it distributes the force over a longer length of material.

Spring Type: Different spring types (compression, extension, and torsion) have different spring rates depending on their design and use.

Applications of Spring Rate

In many professions, it’s essential to comprehend and effectively implement the idea of spring rate.

Automotive Industry: The spring rate of a vehicle’s suspension system affects the handling and ride quality. A firmer ride with a higher spring rate can improve handling but also reduce comfort.

Manufacturing and Machinery: A variety of machinery uses springs to provide controlled motion, maintain tension, and absorb shock. Proper selection of the spring rate is necessary to ensure the equipment’s longevity and optimal performance.

Consumer Products: Products like mattresses, pens, and even electronic devices use springs with precise spring rates to achieve desired functionality and user experience.

Accurate spring rates are required for the correct operation and dosage control of medical equipment, including syringes and inhalers.

Calculating Spring Rate

To calculate the spring rate, one must consider the spring’s dimensions and material properties. For a cylindrical coil spring, the spring rate can be approximated using the formula:

where:

- d is the wire diameter,

- G is the modulus of rigidity of the material,

- D is the mean coil diameter,

- N is the number of active coils.

The spring rate is a critical consideration in the design and use of springs in a wide range of industries. Engineers and designers can choose and create springs that satisfy specific performance requirements, ensuring usefulness, safety, and efficiency, with a solid understanding of the spring rate. The correct application of spring rate principles is critical to mechanical design and engineering, whether it is in a watch’s intricate mechanism or an automobile’s suspension system.