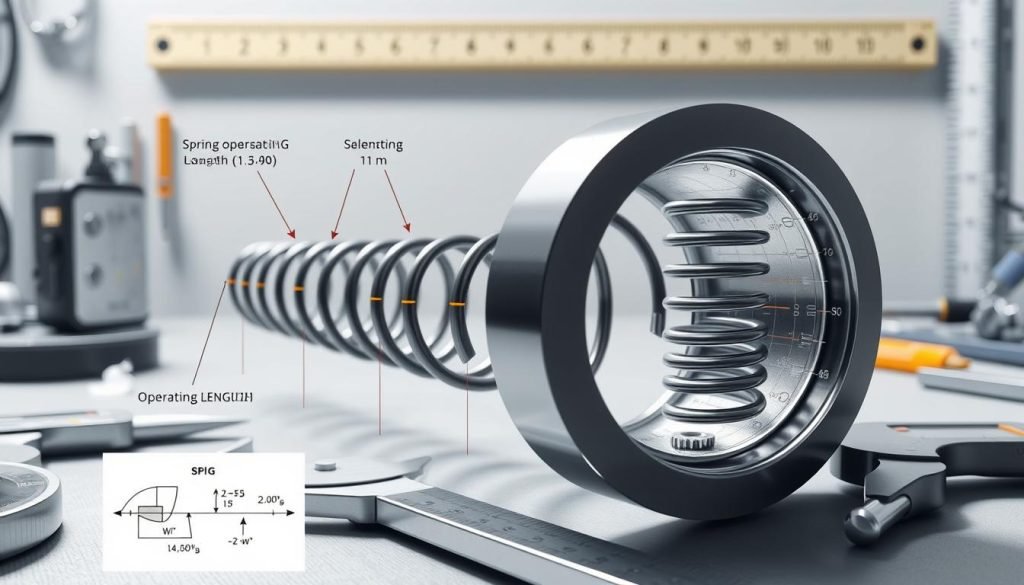

When designing springs, the operating length is key. It affects how well a spring works. Knowing how to calculate this length is essential for a spring’s performance.

In spring design, knowing the operating length is critical. It’s important in many fields, like cars and planes. By understanding this, designers can make springs that work better, improving products overall.

Understanding What is an Operating Length for a Spring

When we talk about springs, the operating length is key. It’s the distance a spring can move from its free length to its compressed or extended state. The operating length is important for a spring’s performance and how long it lasts in different uses. The material of the spring, like steel, aluminum, or copper, also affects its operating length and how well it works.

In industrial settings, knowing a spring’s operating length is critical for its best performance and safety. For example, in machines, the right operating length helps keep things stable and prevents damage. The material of the spring can also change how long it can operate, with some materials better for certain jobs than others.

Basic Definition and Concepts

The operating length of a spring is found by measuring from its free length to its compressed or extended state. This measurement is key to understanding a spring’s performance and how long it will last. Other things like the spring’s design and how it’s made can also change its operating length.

Why Operating Length Matters

The operating length of a spring is very important for its performance and how long it lasts. If a spring’s operating length is off, it can work less well, wear out faster, and even break. In industrial settings, this can mean expensive fixes, lost time, and less work done. Knowing a spring’s operating length helps makers and engineers create better, more reliable systems.

Different Types of Spring Operating Lengths

There are many kinds of spring operating lengths, each with its own uses and features. These include:

- Static operating length: This is how far a spring can go without moving or shaking.

- Dynamic operating length: This is how far a spring can go while it’s moving or shaking.

- Cyclic operating length: This is how far a spring can go in a cycle of squeezing and stretching.

Knowing about these different operating lengths helps makers and engineers design springs that fit their needs. This is true for things like industrial machines, cars, or other places that use springs and need them to work well.

The Components That Affect Spring Operating Length

When we talk about spring design, many parts are key to the spring’s operating length. The spring’s type, material, and design all play a part. Knowing these is vital for getting the spring’s operating length right.

The type of spring matters a lot. Springs like compression or extension springs work differently. The material also affects the length. For example, springs made from elastic materials have a different length than those made from less elastic ones.

Other things like the spring’s diameter, wire size, and coil count also matter. These can be changed to get the right length and performance. By thinking about these and using the right operating length calculation, we can make springs that work well.

To understand what affects spring operating length, consider these points:

- Spring type: compression, extension, or torsion

- Material: metal, plastic, or composite

- Design parameters: diameter, wire size, coil count

By keeping these in mind and using accurate operating length calculation methods, we can make springs that work great. They’ll perform well in many situations.

How to Measure Spring Operating Length

Measuring the operating length of springs is key to their performance. This involves spring testing and using specific measurement techniques. These steps help find the spring’s operating length.

First, you need the right tools like a caliper or ruler. These help measure the spring’s length accurately. Here are the tools you’ll need:

- Caliper or ruler

- Spring testing device (if applicable)

- Measuring tape or string

Step-by-Step Measurement Process

The measurement process has several steps. You’ll measure the spring’s free length, compressed length, and extended length. By following these steps and using the right measurement techniques, you get accurate results.

Common Measurement Mistakes to Avoid

Some common mistakes include wrong calibration, ignoring spring deformation, and recording errors. Knowing these mistakes helps you avoid them. This ensures your spring testing is accurate.

| Measurement Mistake | Prevention Method |

|---|---|

| Incorrect calibration | Calibrate measuring devices regularly |

| Failure to consider spring deformation | Use a spring testing device to account for deformation |

| Inaccurate recording of measurements | Use a reliable recording method, such as a spreadsheet or data logger |

Spring Operating Length in Different Industries

Spring operating length is key in many industrial applications. This includes the automotive, aerospace, and medical fields. Each industry has its own needs and challenges, requiring the right spring materials and length.

In cars, springs are vital for suspension, engine valves, and transmissions. The right length is essential for safety and performance. A wrong length can harm fuel efficiency, stability, and safety.

Here are some industries that use springs and their needs:

- Aerospace: They need strong, light spring materials for planes and space.

- Medical devices: Accurate length and spring materials are key for implants and tools.

- Automotive: Cars need durable spring materials and precise length for suspension and more.

In summary, spring length is critical in many fields. Choosing the right spring materials is vital for performance and safety. By understanding each industry’s needs, manufacturers can create better springs.

Calculating Optimal Spring Operating Length

When designing springs, figuring out the right operating length is key. This step looks at the spring’s material, design, and the environment it will be in. The operating length calculation is vital for the spring’s performance and how long it lasts.

Engineers use formulas to find the best operating length. These formulas consider the spring’s wire and coil sizes, among other things. By using these values, engineers can make sure the spring works as needed.

Important things to think about when calculating the operating length include:

- Spring material and its properties

- Design parameters, such as wire diameter and coil diameter

- Environmental factors, such as temperature and humidity

There are many software and tools to help with spring design and operating length calculation. These tools make it easier for engineers to get the right length quickly and accurately. This saves time and cuts down on mistakes.

| Spring Type | Operating Length Calculation |

|---|---|

| Compression Spring | L = (n \* d) + (d \* 1.5) |

| Extension Spring | L = (n \* d) + (d \* 2) |

By following these steps and using the right tools, engineers can get the operating length calculation right. This leads to effective spring design that meets all the necessary standards.

Common Problems with Spring Operating Length

Several common problems can happen with spring operating length. These include spring failure and operating length issues. These issues can come from bad design, poor maintenance, or unexpected weather.

Some common problems with spring operating length are:

- Insufficient operating length, leading to spring failure

- Excessive operating length, resulting in reduced spring performance

- Corrosion or wear and tear, affecting the overall spring operating length

To solve these problems, it’s key to know why they happen. By understanding spring failure and operating length issues, designers and engineers can find ways to avoid or lessen them. This ensures springs work well and last longer.

Knowing these common problems helps us design and keep springs reliable. This way, we can lower the chance of spring failure and operating length issues.

Maintaining Proper Spring Operating Length Over Time

Regular spring maintenance is key to keeping springs working well for a long time. Springs can lose their length over time due to wear and tear. This can make them less efficient and more likely to fail. It’s important to watch the spring’s operating length and do regular maintenance.

Here are some tips for keeping springs at the right length:

- Regularly check springs for wear and tear signs

- Do operating length monitoring to spot any length changes

- Lubricate springs to cut down on friction and wear

By following these tips and keeping up with spring maintenance, your springs will work better. It’s also key to know the signs of spring length problems. Look out for less spring force or more vibration. If you see these signs, act fast.

Remember, keeping an eye on operating length monitoring and maintenance can make your springs last longer. It can also save you money on repairs or new springs. By focusing on spring maintenance and watching for length issues, you can keep your springs running smoothly for years.

Design Considerations for Spring Operating Length

When designing springs, several key factors must be considered for optimal performance. The operating length calculation is critical. It determines the spring’s length for the best functionality. This calculation considers the spring’s material, diameter, and wire size.

Designers must weigh the trade-offs during the design process. A longer spring offers more flexibility but may buckle or become unstable. A shorter spring is more stable but might lack flexibility. By balancing these factors, designers can create a spring design that meets performance needs.

Important considerations in operating length calculation include:

- Material selection: Different materials affect the spring’s stiffness and strength.

- Design parameters: Diameter, wire size, and coil shape impact the spring’s performance.

- Environmental factors: Temperature, humidity, and other conditions affect the spring’s behavior.

Designers use specialized software or tools to consider these factors. This helps create a

| Factor | Description |

|---|---|

| Material selection | Affects the spring’s stiffness, strength, and durability |

| Design parameters | Influences the spring’s operating length, flexibility, and stability |

| Environmental factors | Impacts the spring’s behavior and operating length in different conditions |

Conclusion: Making the Most of Your Spring Operating Length

As we wrap up our look at spring operating length, it’s clear how vital it is. It ensures your spring systems work well, safely, and last longer. By knowing what affects operating length, how to measure it, and how to maintain and design it, you can unlock the full power of your spring’s operating length. This leads to amazing results in your projects.

If you’re an engineer, designer, or maintenance expert, using the tips from this article will help you make better choices. You’ll avoid mistakes and create top-notch spring solutions. By focusing on spring operating length, you’ll improve performance, reliability, and save costs over your spring’s life.

Keeping an eye on spring operating length is more than just a technical task. It’s a chance to get ahead of the competition and offer great value to your customers or stakeholders. Use this knowledge, apply it, and see how it changes your spring projects for the better.