Richconn’s Robust R&D and Manufacturing Skills

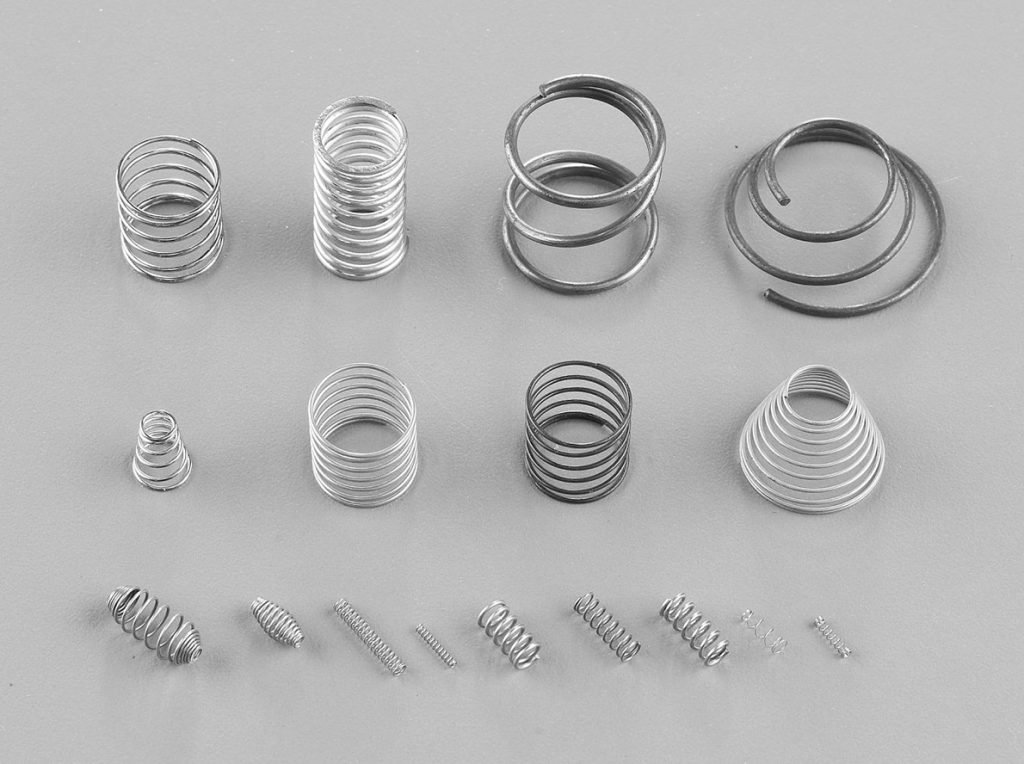

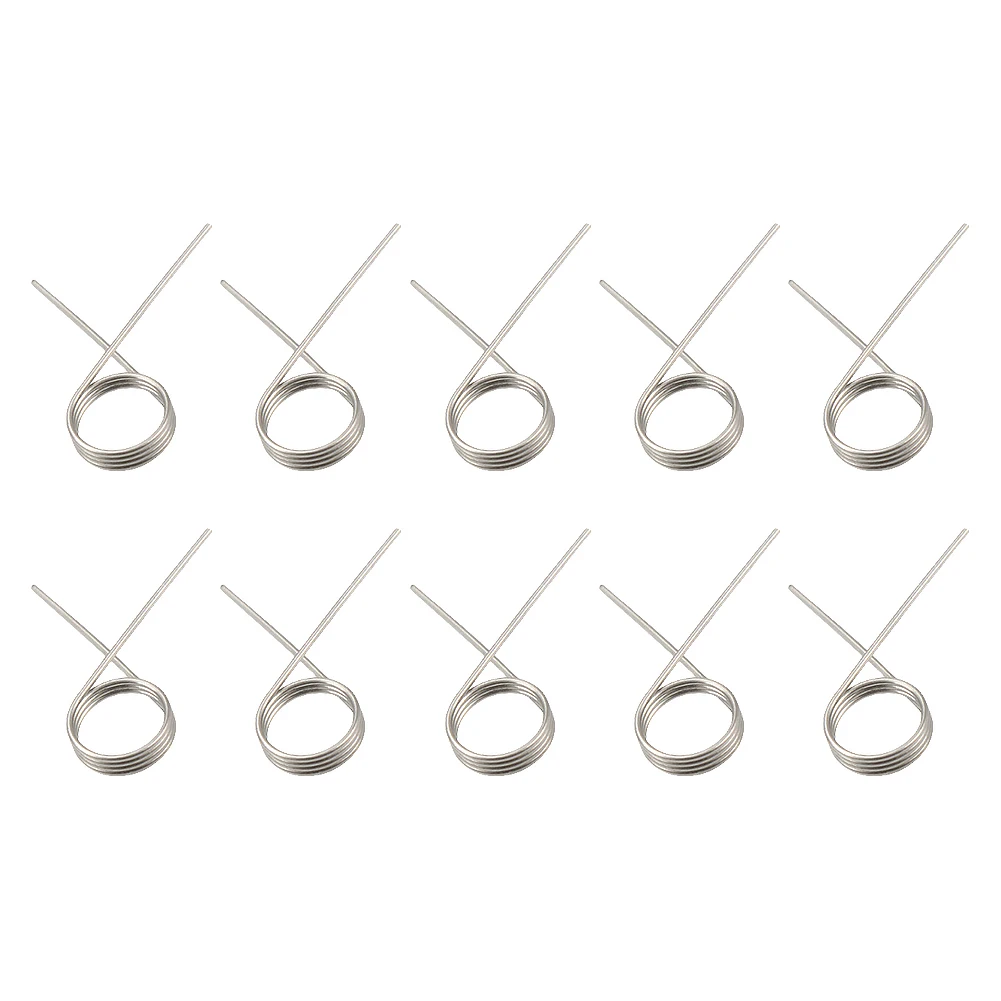

Richconn has a highly skilled research and development staff that is committed to constantly inventing and improving micro spring designs. We are able to meet a wide range of complex needs and high-precision demands for small springs by integrating state-of-the-art production equipment and cutting-edge technologies. From conceptual design to product development, our R&D team works directly with clients to make sure that every custom small spring precisely matches their unique requirements. Richconn’s strong R&D resources enable us to react quickly to customer needs and market shifts, producing micro spring products that are very dependable and high-performing, enabling our customers to prosper in a cutthroat industry.

我們的服務

我們的服務